Calling all sublimation beginners and those looking to get into the industry! Today, I’ll break down what sublimation is and the equipment and products you need to get started.

What is Sublimation?

Sublimation is a process that uses heat and pressure to turn solid ink directly into a gas, allowing it to permanently bond with the surface of a material.

Here’s a simple breakdown of the process

1.Print your design onto transfer paper using sublimation ink.

2.Place the printed paper onto your product and load it into the heat press.

3.Under precise high heat and pressure, the ink on the paper sublimates—turning into a gas.

4.This gaseous ink rapidly penetrates and solidifies within the molecular structure of the substrate, becoming one with the item’s surface.

The biggest advantages

*Durability:The print is permanent, won’t fade, crack, or peel.

*High Quality: It produces photo-realistic, vibrant images with incredible detail.

*Smooth Feel: The design becomes part of the product, leaving no sticky or raised texture.

Essential Sublimation Equipment & Supplies

1.Printer: You must have an inkjet printer dedicated to sublimation, filled with sublimation ink. Regular printers will not work.

2.Transfer Paper: Special sublimation paper is required to hold the printed design.

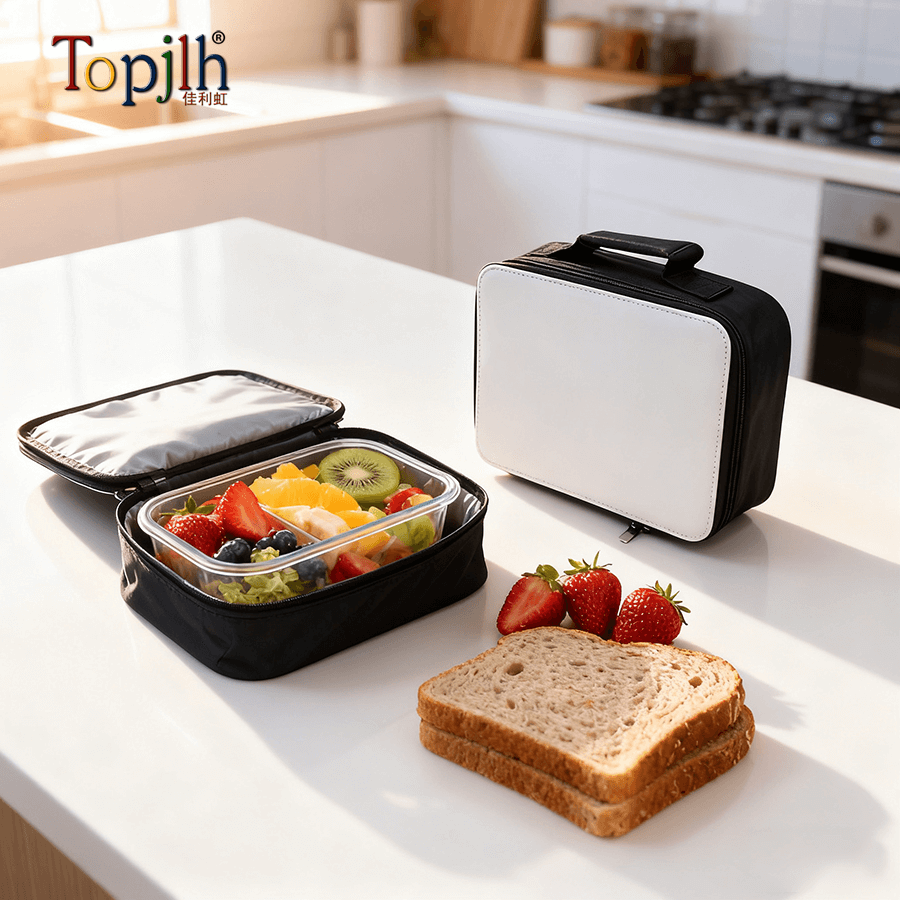

3.Sublimation Blanks (Products): You can only sublimate onto items with a polyester coating or polymer surface. Common examples include: mugs, phone cases, coasters, tote bags, photo frames, metal sheets, and keychains.

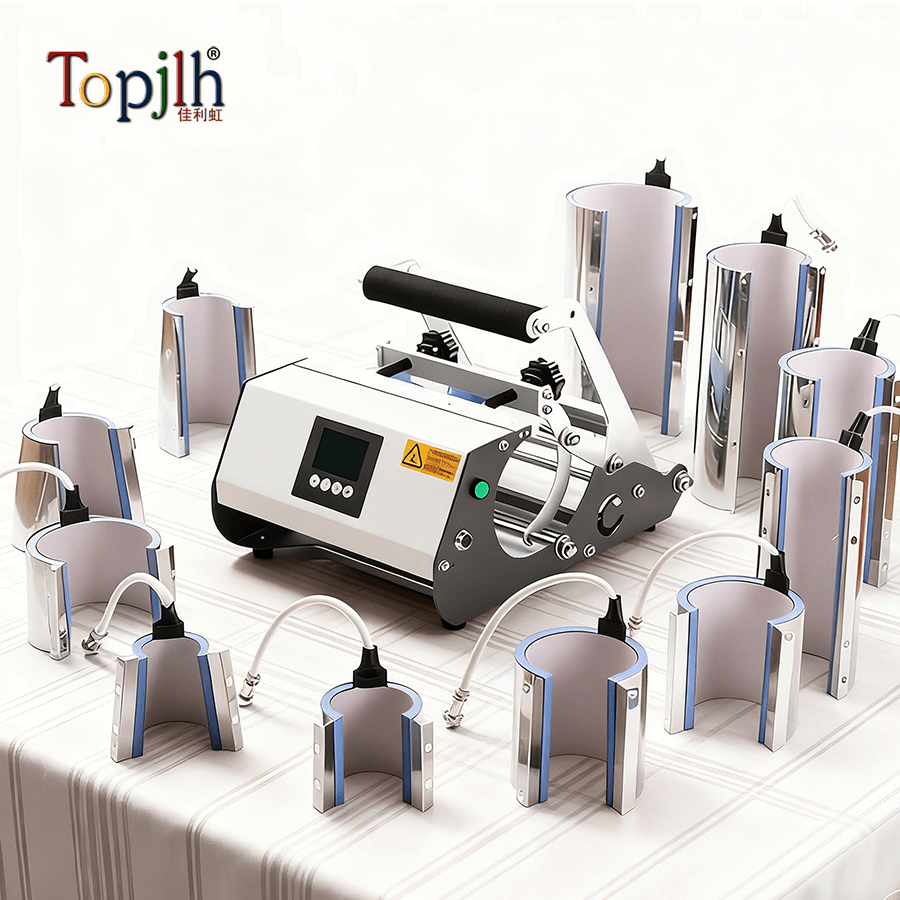

4.Heat Press: The type of press depends on the product shape. Options include a Flat Press (for flat items), Mug Press (for mugs), Cap Press (for hats), 3D Vacuum Press (for curved surfaces like phone cases), or even an Oven (for batch processing metal items).